Standards and Student Projects

Polymers Properties Course Work Increases Understanding of ASTM Standards

Many of the students at Kettering University in Flint, Mich., undertake cooperative work assignments in the manufacturing sector, where they encounter plastics product design and testing. From their need to understand plastic processing and design, the plastics curriculum was developed. Students benefit from plastics course work that includes polymer chemistry, processing, material selection and part design. The materials selection course, Polymer Properties, provides students with an understanding of the relationships between composition and polymer processing, and an ability to select appropriate polymers for design applications.

In their cooperative work assignments, students are presented with a wide range of behaviors for a single component manufactured from a single polymer. Thus, there is benefit from seeing the relationships between chemistry, processing and properties for a polymer under a controlled test environment. ASTM International's standardized test procedures provide a framework for understanding the importance of such control. The standardization of testing conditions underscores the potential for variability in test results, and students learn to apply such specificity when prescribing testing for complexly shaped parts. Accurate and repeatable tests allow for the consistency necessary for design.

The Polymer Properties course begins with a discussion of polymer synthesis. Students are given the chance to apply their polymer chemistry knowledge by identifying correlations between synthesis techniques and architecture for various commodity plastics. Subsequent to this, students study the impact that various polymer processing techniques have on physical properties such as crystallinity and molecular weight. Components that have been produced by students in the Polymer Processing course are examined; students observe the physical effects of various cooling conditions on component geometry. A wide range of mechanical properties is demonstrated for components manufactured from the same polymer under a range of process conditions. The stage is set for a discussion of testing standards.

At this point in the course, a thorough discussion of mechanical and thermal properties is undertaken, and the correlation between each property and the physical bonding within the polymer is described. ASTM International test methods for mechanical properties such as strength and impact toughness, and for thermal properties such as viscosity and glass transition temperature, are presented. The most commonly used of these are presented in Table 1. The development of these tests for polymers, and how the tests differ from those for metals and ceramics, is critical to understanding polymer properties and their dependence on structure. The advantage of following detailed test specifications can be fully appreciated, as students can at this point recognize the dependence of polymer properties on process and test conditions.

The Polymer Properties course culminates in student projects. Each student selects a relatively common plastic part to examine, such as clothes hangers, rulers, pocket combs and kitchen utensils. Students create a list of properties critical for their products while in service. From this discussion, each student generates a list of mechanical and thermal properties that must be measured and maintained for their product. They compare this list to the ASTM test methods previously discussed.

While returning to the topic of ASTM International standards, students are required to devise a test for their specific product, based on a current ASTM standard for plastics. Effects of load rate, temperature, humidity and failure mode are examined one more time, and students are then charged with developing a test specific to their polymer component. Students are required to follow ASTM format in presenting the test specifications they develop for their unique products. These test standards might include those listed in Table 2.

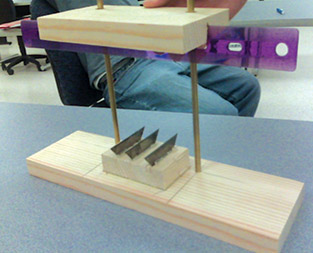

Students must write with clarity because tests are conducted by individuals unfamiliar with the product. The photo illustrates two test methods developed in recent classes: a razor impact test for measuring the shatter resistance of a ruler and the hardness of its edge, and a drop test for measuring the toughness of the cap on a water bottle.

On completing the Polymer Properties course, students have a foundation in the unique and complex behavior of polymers, and an appreciation for ways that this behavior can be modified and controlled during processing. The interaction between polymers and the mechanical and thermal stresses to which they are subjected is also a topic that students come to appreciate, and they are thus suited to make polymer materials selection choices appropriate to particular service environments. All of these concepts are made clear by incorporating ASTM International standards for plastics into the Polymer Properties curriculum. The unique hands-on experience of following and prescribing test standards serves to reinforce this understanding and to help integrate knowledge in polymer structure, processing and design.

Laura Sullivan, Ph.D., has been a faculty member at Kettering University, Flint, Mich., for 20 years, teaching courses in manufacturing, materials and mechanics. Outside the classroom, Sullivan serves as an ABET evaluator and advises the Kettering University chapter of Engineers Without Borders - USA, assisting with projects in Mexico and South Africa.Student-devised impact test for measuring shatter resistance and hardness of a ruler.

Table 1 - Polymer Properties Discussed and Corresponding ASTM Standard Tests

| Topic | ASTM Standard Discussion |

| Flow Behavior: Newtonian, non-Newtonian, elongational and shear flow, thermal transitions and viscosity | Melt flow rate (D1238, Test Method for Melt Flow Ratesof Thermoplastics by Extrusion Plastometer); transition temperatures by DSC (D3418, Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry); and determination of properties by capillary rheometry (D3835, Test Method for Determination of Properties of Polymeric Materials by Means of a Capillary Rheometer) |

| Mechanical Behavior: deformation, strength, stiffness, yield, ductility, creep, stress relaxation | Tensile properties of plastics (D638, Test Method for Tensile Properties of Plastics); Izod pendulum impact resistance (D256, Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics); and tensile, compressive and flexural creep, and creep rupture of plastics (D2990, Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics) |

Table 2 - Required Standard Test Procedure Components

| Product Description | Illustration of product, including dimensions, color, finish and component parts where applicable |

| Service Conditions | Mechanical and thermal stresses experienced under normal and extreme conditions |

| Test Setup |

|

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor