By Daniel Bergels

Jul 26, 2016

A young ice hockey player and his dad go to an ASTM committee meeting. Five years later, a new standard will help protect the throats of goalies.

When a young ice hockey player's protective gear breaks from a flying puck, there is often a nervous moment in the bleachers where the parents sit.

When that happened to the throat protector of 14-year-old AJ Ostrander for the fourth time - and it shattered into several pieces on the ice - his father Jerry said, "Something's not right here."

The elder Ostrander started asking around. The other parents, players and coaches all told him some version of the same story: Yes, the throat protectors that are attached to the bottom of the goalie's mask sometimes break. And each time that piece breaks, games have to be delayed to find a replacement.

But with relatively low replacement costs - and no reports of serious injuries - no one had made a concerted effort to fix the problem.

Ostrander was particularly concerned because he suspected that some goalies in his son's league or elsewhere might simply continue to play with broken throat protection, or without protection altogether. Without that piece of protective equipment, the larynx, trachea, esophagus, cartilage, vocal cords and more would be vulnerable.

The retired police officer said, "I spent 25 years protecting people, but I didn't feel like our kids were being protected."

He started writing letters to a number of organizations and U.S. federal agencies that deal with health and safety. When someone pointed him to ASTM International, he went online and saw that ASTM was the home for several ice hockey equipment standards within Committee F08 on Sports Equipment, Playing Surfaces and Facilities.

"Aha!" he thought, "I finally landed in the right spot."

However, Ostrander quickly realized that there was no safety standard at ASTM - or any other body - for throat protectors.

The Process Begins

Ostrander was undeterred. He got the contact information for Mark Granger, the chairman of Subcommittee F08.15 on Ice Hockey, and called him.

Granger was pleasantly surprised to hear directly from a consumer about a potential new standard in this area. Remembering ASTM's openness to anyone interested in developing standards, he advised Ostrander to submit a letter that he could then share with his fellow members of that subcommittee.

It was clear that Ostrander had done his homework. He sent a detailed letter to Granger in January 2010, requesting that the group draft a consensus standard for "polycarbonate hanging goalie throat protectors." The letter told how AJ had been playing goalie since age seven in a local hockey league and had just started playing in high school.

"There's something breaking, and your committee can fix it!" Ostrander summarized at the end of the letter.

Granger put the topic on the agenda for the next in-person meeting of the group in St. Louis, Missouri, that May.

"I'll be there," Ostrander told Granger. "And I'm bringing AJ."

Task Group Gets to Work

When someone comes to ASTM and proposes a new standard, a task group is often formed to explore the idea. That's what happened in this case.

David Rudd, the senior development manager at Bauer Hockey, volunteered to lead the effort. Granger decided to be part of it. And, Jerry and AJ joined the group.

Rudd said, "Our initial observations were that we didn't have reports of injuries, but we did see some reports of breakages of throat guards," Rudd said. "We knew we could do even more to protect the throat and address this concern, so our task group got to work."

The manufacturers started determining key requirements that should be in the standard, including how the protectors were constructed and attached to the mask, product markings for consumers and more.

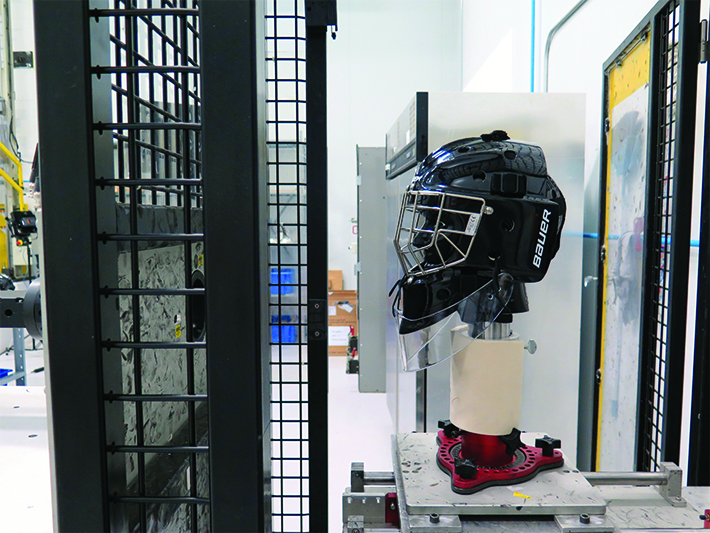

Then they developed and used a performance test, which involved shooting high-velocity hockey pucks from an air cannon at a headform mounted with a mask and throat protector (see Figure 1). This test method also became part of the standard itself.

Figure 1 - Throat protectors conforming to a new ASTM standard are tested using a puck launched at the mask and protector mounted on a headform.

Crossing the Finish Line

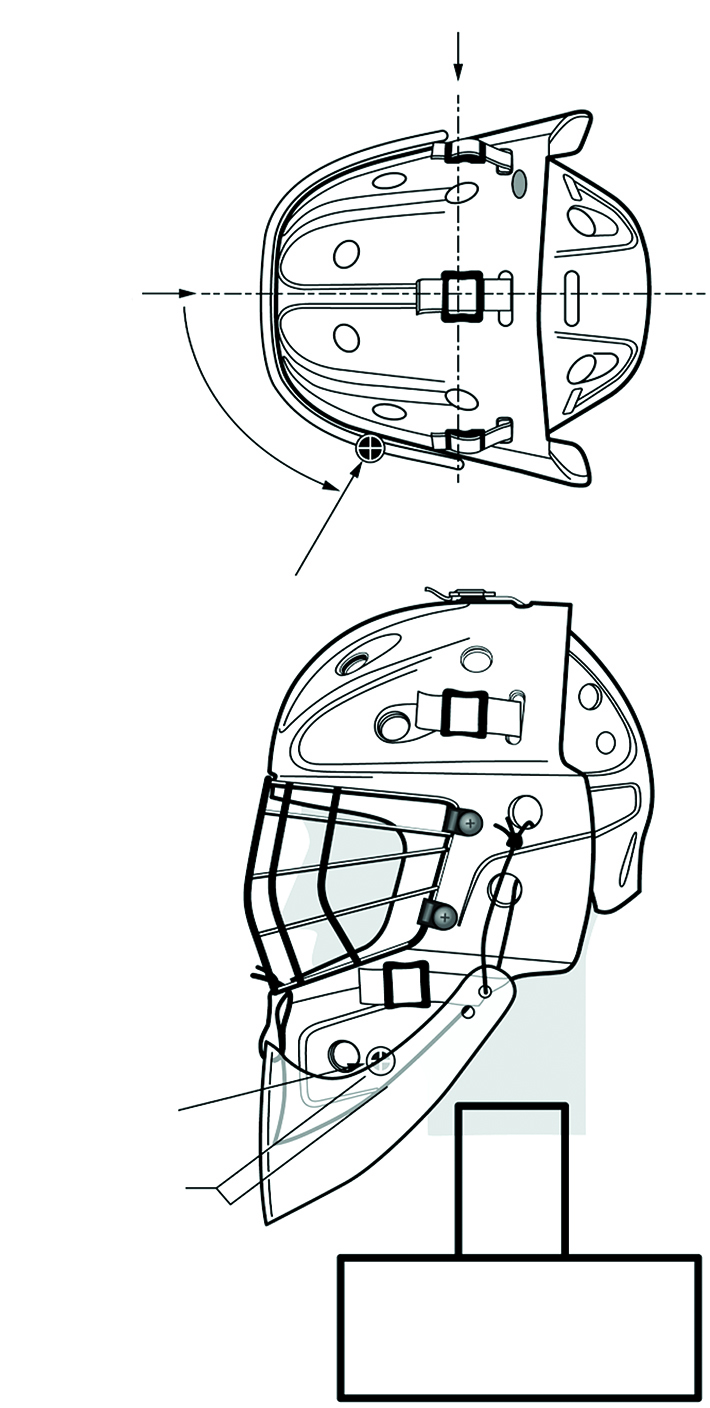

The data came together, and the new standard started taking shape, complete with descriptions and drawings (see Figure 2).

Figure 2 - One of the F3165 standard drawings illustrates the throat protector installation and overlap.

In May 2015, Jerry and AJ went to another ASTM meeting, this time in Anaheim, California.

Toward the end of the meeting, it became clear to the subcommittee that the standard could soon cross the finish line.

Granger asked Jerry and AJ to stand up. Now 19 years old, AJ had clearly grown up a bit. The ASTM members gave them a round of applause.

Granger, an ASTM member since 1994, said, "In essence, what AJ did was create an international standard for this piece of gear at the youngest age I've ever seen."

The standard, which was approved on March 15, is now on the books: F3165, Specification for Throat Protective Equipment for Hockey Goaltenders.

Now a junior at Coastal Carolina University, AJ still plays hockey on occasion, even though the nearest rink is a few hours away. Although he has been instrumental in the development of the new standard, he's still impressed with how it all came to be.

"I think it's pretty cool how it started with my dad and me," AJ said. He's thrilled that the throat protector standard is "something so small, but it can make a big impact."

Because the Hockey Equipment Certification Council has used several ASTM standards, Granger said he expects them to use the new standard. He added that other organizations could follow suit, helping further ensure safety for the youth and adults who play ice hockey.

May / June 2016