Making Gates Safer

Making Gates Safer

If fencing is one of humanity’s oldest innovations, with examples dating back to early civilizations in Mesopotamia, the gate can’t be too far behind.

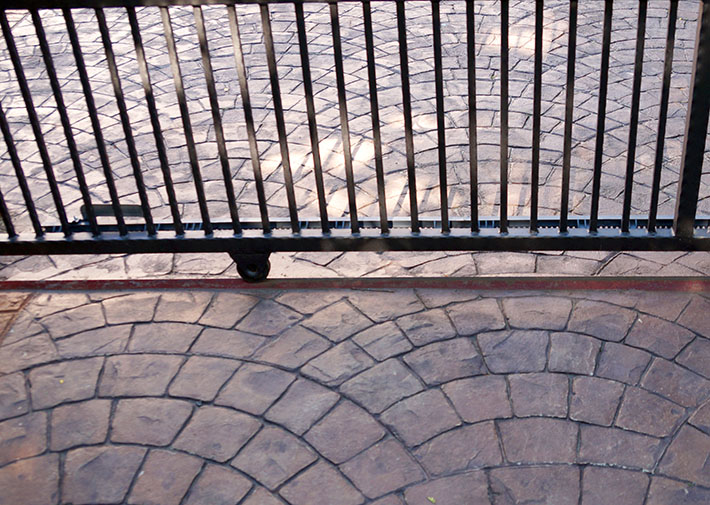

Gates have come a long way in the last 10,000-plus years, now including everything from swing gates to powered lift gates, vertical pivot gates, turnstiles, automatic gates, and more. Among the more common types is the horizontal slide gate, which uses less space than a swing gate while also being inexpensive to install and simple to maintain, given that they can be manually operated rather than powered. That’s why you’ll find these types of gates worldwide, in both rural and urban areas, protecting a wide range of properties.

That ubiquity, however, comes with some downsides. Since they can, and often are, installed just about anywhere, manual slide gates can present hazards.

READ MORE: 7 Ways Standards Make Summer Safer

“There are a lot of slide gates out there that when you open them, they will shut on their own, either because they're installed on a hill or are not being designed property for safety,” says Ben Shirley, director of marketing at ASSA ABLOY’s Ameristar Perimeter Security USA and chair of the committee on fences (F14). “They can be dangerous. Imagine opening a gate to allow a truck through, and it slides closed midway and hits a door or side panel. Or, worse, injures someone while they’re using it. These gates are heavy – they can do real damage.”

Given these risks, F14 has for years maintained standards for both automated and manual slide gates, including the specification for industrial and commercial horizontal slide gates (F1184) for the latter. The standard covers rolling, cantilever and overhead slide chain link fence gates, gate posts, and accessories for industrial and commercial applications. However, because there isn’t much innovation happening in gate technology, updates have been rare. But recently, safety concerns have spurred the committee to expand and clarify F1184.

“We've seen issues throughout the years such as poor installations leading to unsafe gates,” Shirley says. “So we decided we needed to address them in the standard for manual gates. Many of the additions are very similar to what is in the current version of F2200, which is the standard for automated gates.”

The specific revisions include:

1) Classification of gates: In addition to the existing types of horizontal slide gates addressed in the standard – including overhead slides, which are supported only from above, and cantilever slides, which span an opening without any top or bottom support when closed – the updated standard now includes a third type: rolling gates. These are defined as any horizontal slide gate that requires support on grade to traverse the gate opening. This was a particularly important addition, Shirley says, “because there are hundreds of thousands of them out in the market. It’s probably the most widely used type when it comes to manual slide gates.”

2) Movement Limitations: Under the new standard, manual slide gates must be designed and installed in such a way as to not fall over more than 45 degrees when detached from their supporting hardware. In addition, positive stops are required to limit the movement of the gate to ensure that it doesn’t go beyond fully open or fully closed. For instance, in the event that a closed gate becomes unlatched, without stops in place it could potentially derail, potentially injuring anyone nearby. This new addition to the standard is intended to prevent that from happening.

3) Covered Rollers: All weight-bearing and exposed rollers used in manual slide gates now need to be guarded or covered to reduce potential pinch points where fingers or toes can get caught.

4) Installation Guidelines: Manual slide gates should be installed in such a way that they cannot move on their own due to the force of gravity. What’s more, the gap between the gate frame and its support posts cannot exceed 2.25 inches, to further prevent the chance of a pinch injury or someone getting caught in the gate.

“For years, this standard covered two very popular types of gates,” Shirley says, “but the addition of a third type – rolling gates – now addresses a gate type that is common because it is affordable. It's a less expensive version. By adding that gate type, we now cover every slide gate imaginable without a doubt and can ensure that all of them are safe.”

Tim Sprinkle is a freelance writer based in Colorado Springs, Colorado. He has written for Yahoo, The Street, and other websites.