In at the Ground Floor

Service bureau Met-L-Flo uses existing ASTM standards for the manufacture of parts and is participating in the development of new 3D printing standards to help refine and improve their processes.

Requirements are constantly changing when building custom products for clients. Using additive manufacturing helps standardize some of this tremendously. While 3D printing can be much easier to use than conventional fabrication technologies, this still leaves a number of variables - color, strength, material characteristics, and levels of accuracy - that create a collection of points to be controlled. Ensuring that these details are addressed is critical to client satisfaction and repeat business.

Additive manufacturing has been a part of the service bureau Met-L-Flo's solution for our clients since the early 1990s. We use a number of additive manufacturing processes in harmony with our secondary casting technologies. These technologies provide solutions for clients in aerospace, defense, medical, and consumer products markets. These markets are very specific and have finite requirements. All of these clients also have specific needs for their unique application. One requirement is constant with all of these programs: material properties.

The use of ASTM test methods such as D638 for tensile testing is one very common way to communicate what a material will handle. This may be one of the common uses of standards that additive manufacturing services are applying at present. Other existing standards are helpful for understanding the materials we are working with, but many new standards are becoming significant for improving the predictability of what these machines can produce.

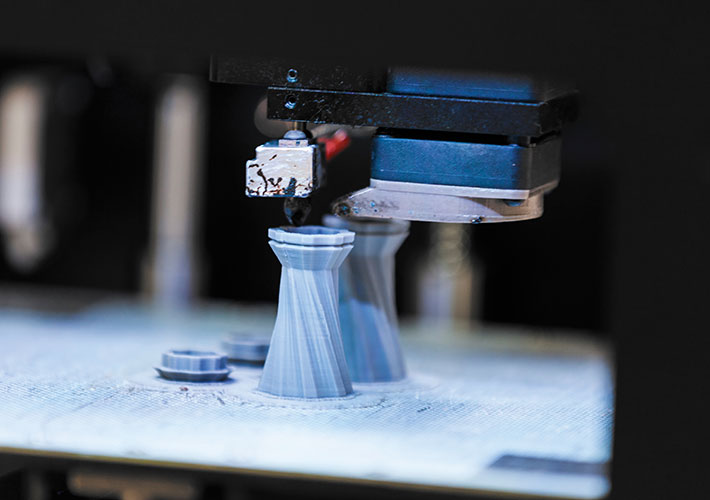

Manufacturers are embracing additive manufacturing as a means to produce low volume, complex geometries. To do this successfully there must be a way to confirm everything was built as expected. Most commonly this includes the use of destructive test samples included in the build area. These provide a level of confidence that everything was built as expected. However, they are only representative samples of the build and for total confidence, additional measures will be beneficial.

New standards being developed in ASTM Committee F42 on Additive Manufacturing Technologies are working toward addressing these methodologies and how to address potential conflicts that come from multiple process-specific requirements. Original equipment manufacturers that are embracing these technologies have had to develop their own specific parameters and processes for product production. This requires manufacturers such as Met-L-Flo to become proficient in numerous methods to produce and validate additive manufactured parts. These independently developed specifications require complex and difficult procedures and controls to ensure all product is produced within acceptable specifications.

Until these new standards are developed and used by all original equipment manufacturers, component providers like Met-L-Flo need to apply all possible available standards to minimize the deviation potential and ensure the quality needed for rigorous applications. One standard that has helped greatly with preparing raw materials for manufacturing products is D1238, which enables a batch of thermoplastic powder to be controlled within a repeatable range, helping ensure the outcome of the build will meet expected properties. As more of these standards are implemented, the comfort that the product will meet the expected outcome goes up.

The use of these standards to validate products and ensure the conformance of the feedstock materials enhances processes and the products' success rate. These incremental improvements continue to advance what can be done with the technologies and how they are applied. Additional standards are being evaluated and utilized in developing the next generation of standards that will advance these processes into a matured technology.

Met-L-Flo continues to help develop standards in Committee F42 while also using other industry standards that apply to additive manufacturing. As these processes become more standardized we will see greater use of 3D printing as a method of manufacturing. This will lead to technology expansion and a way to take advantage of economies of scale for machines and materials. We are on the cusp of an explosion of additive manufacturing technologies and applications, aided by the promulgation of standards.

Carl Dekker is president of Met-L-Flo Inc., and he is a member of ASTM Committee F42 on Additive Manufacturing.

Company Snapshot

- Service bureau using additive manufacturing and other processes for product design, inspection and metrology, prototyping, bridge tooling, and manufacturing

- Trading area: North America

- Number of staff who serve on ASTM committees: 1

- ASTM technical committees with Met-L-Flo representatives: F42

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor