Standards Help Serve Critical Testing Needs

Product Evaluation Systems, Inc. is an independent, accredited materials-testing laboratory that is ISO/IEC 17025:2017 certified and Nadcap accredited for materials and nondestructive testing. Our facility in Latrobe, Pennsylvania houses a metallurgical laboratory, machine shop, mechanical, chemical, and nondestructive testing facilities. PES currently holds various customer approvals, including Pratt & Whitney, GE, Rolls-Royce, Lockheed Martin, and Safran (AMS2300).

Our experienced team members commit to projects of all types and sizes, as well as all materials and testing requirements. We proudly serve the critical testing needs that are specific to major industries including, but not limited to: additive manufacturing, aerospace, oil & gas, mining, power generation, and steel manufacturing.

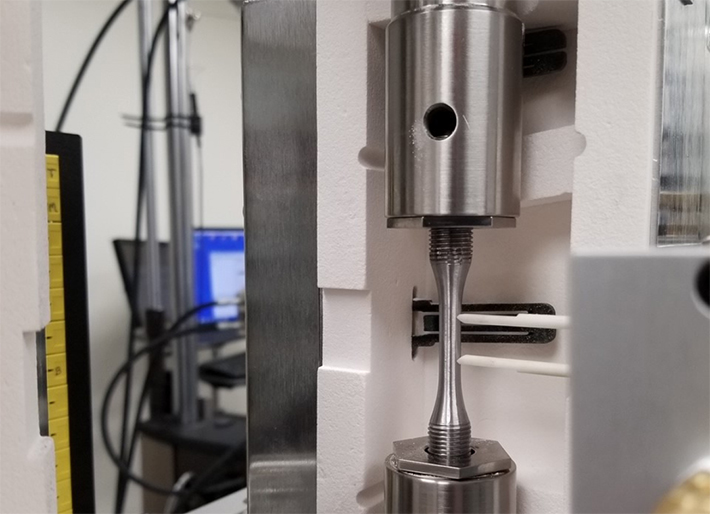

Every order that is fulfilled is tested in accordance with a specific standard and/or testing specification. In our day-to-day queue, standards from ASTM International are used abundantly, but our testing capabilities are not limited to just ASTM standards. In our mechanical laboratory, we use the following ASTM standards:

- Standard practice for conducting force controlled constant amplitude axial fatigue tests of metallic materials (E466)

- Test method for strain-controlled fatigue testing (E606)

- Test method for measurement of fatigue crack growth rates (E647)

- Test methods for tension testing of metallic materials (E8)

- Test methods for elevated temperature tension tests of metallic materials (E21)

- Test method for linear-elastic plane-strain fracture toughness of metallic materials (E399)

- Test method for measurement of fracture toughness (E1820)

These are some of our more common mechanical testing capabilities. The determination of mechanical properties is fundamental to the design, manufacture, and implementation of products in everyday life. It is critical that as an organization, we ensure data integrity as we adhere to the specific testing specification/standard that is required.

PES has the capability to conduct chemical analyses on a wide variety of alloys and carbide materials. Testing/analysis in the chemistry lab includes but is not limited to: ICP-OES testing (E3061, E1277, E2371, and E2594); testing on the Spectro MAXX OES Spark (E415, E1086, E1251, E2209, E3047, and A751); and testing on the LECO CS 400; TC 400; and RHEN 602 (ASTM E1019, E1941, and E1447).

In the metallurgical laboratory, our talented metallographers and engineers analyze, characterize, and photo document microstructural and macrostructural features that are present in a wide array of different metallic and cemented carbide materials. Microstructural evaluation such as surface contamination (alpha case/alloy depletion) is a part of our daily MET tasks, which utilize ASTM standards E3 and E407. Some other metallurgical analyses conducted include: grain size measurement (E112 and E1181), Vickers (macro/micro), Knoop (E92 and E384), and macro-etching examination (E381 and A604).

ASTM Standards as well as other standards/specifications are frequently used in the testing procedures/guidelines that are followed in our daily testing queue. These standards are in place to ensure the testing is completed accurately so that our customers receive data with the knowledge that it is accurate and tested according to specifications to ensure safety and quality. Quality is at the top of mind in everything that happens at PES, and we work hard to provide our customers with a seamless experience every time. ■

Company Snapshot

Product Evaluation Systems, Inc.

Headquarters: Latrobe, PA, USA

Description: PES Testing is a full-service, independent materials testing laboratory that is Nadcap and ISO/IEC 17025 accredited.

Industries serviced: Aerospace, Additive Manufacturing, Oil & Gas, Power Generation, Steel Manufacturing and Mining Services, Mechanical Testing, Metallurgical Testing & Analysis, Chemical Analysis, Nondestructive Testing, Machining

Trading area: Global

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor