Podcast: Additive Manufacturing: Science Fiction vs. Reality

Three-dimensional (3D) printing is transforming industry across a broad range of sectors. ASTM International is the forefront, developing 3D technology through its additive manufacturing technologies committee (F42) and the Additive Manufacturing Center of Excellence (AM CoE). Through F42 and the AM CoE, ASTM is contributing to the advancement of 3D-printing technology throughout the world.

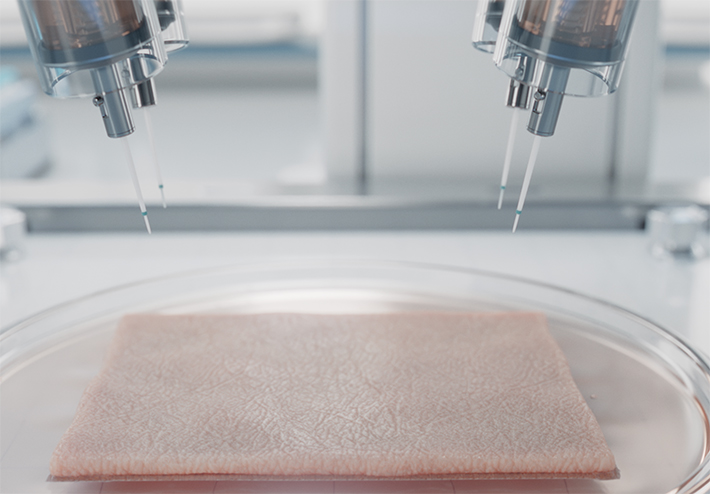

Two areas in which 3D printing holds intriguing possibilities are the aerospace and biomedical realms. Whether it’s used to print spare parts for critical repairs on spaceships or to recreate compatible tissue material for a patient from their extracted stem cells, 3D printing is proving itself to be a technology that has begun to touch all our everyday lives and will continue to do so.

Join host Dave Walsh, editor-in-chief, Standardization News, as he speaks to two guests with extensive experience in additive manufacturing: Christian Seidel, strategic implementation consultant, Wohlers Associates; and Brent Stucker, chief engineer at Nikon, SLM Solutions. Seidel speaks on the importance of 3D printing in aerospace, while Stucker discusses biomedical applications. Both Seidel and Stucker emphasize the importance of standards in the ongoing evolution of 3D printing.

EXCERPT:

Dave Walsh: You've both summed up the role of the AMCOE, and its big picture role where it's convening and promoting research and innovation. But you also both touched on the specific role of standards, and that's what ASTM is the most known for, obviously. I wondered if you could comment on the role that standards will play in the advancement of additive manufacturing technologies, both in aerospace and the biomedical fields, and what would be the most impactful standards that you see currently in development?

Brent Stucker: Well, if I think about the history of standards, it might be helpful to go back in history a little bit before talking about the future, because if we go back about 2008 when we started talking to ASTM as an industry and saying, we need a standards community in additive manufacturing and ASTM could provide the platform for the additive manufacturing community to make standards. Where were we at back then? Well, everybody called everything by different names. Every inventor came up with some name and then they would trademark it, and then the next company would trademark another one. And it was so confusing because I was a professor at the time, even to teach students how to learn about this area of additive manufacturing. We had to give them 10 or 20 different names for each type of machine because everybody would call it different things. And that was really hindering research. It was hindering the ability of companies to even be found as an operator or as a manufacturer who could sell certain technology or services.

So just getting everybody in the world to agree upon it on names of this technology is called this, and that technology is called that and, and to call our industry additive manufacturing. Whereas at the time there was about a dozen different things people even called our industry. So, if you then fast forward to the present, nowadays, anytime anybody wants to procure a machine or buy a service, they, they can use the ASTM-ISO standards that we have. One of the core things that made ASTM so successful, which I just alluded to, is that we joined with ISO, we have a joint standards making community. And so, no matter what we do, people are not hesitant to use the standard because there's not competing standards between ASTM and ISO. It's the same standard. And so that's another unique thing about our industry.

Christian Seidel: That's very important aspects. I can basically only add that the standards will be the fundamental of progress in both industries that you mentioned, but also beyond if there is no standard that's just too much effort, um, for discussions and, you know, case by case, um, discussions on how to proceed. Uh, but if you have a look at the standardization on a high level, I see three phases that we can distinguish. The first one was the kind of setting up the structures, partner standards development organization agreement in place between ICE and ASTM. So that was really the first phase, get everyone aboard and all that. And then there was a second phase in which we developed, the standards. So up to date, you have more than a hundred industry standards available on the market.

They cover a wide range of fields like design terminology, post-processing process, and a lot more. This was the second phase, get standards out there to enable the certification for critical applications and to make benefit to the industry in general to ease business. And I foresee a third phase where we will have to improve these standards that have been published maybe three or four years ago. Every five years you want to look at a standard if it's still relevant. And obviously if you have to develop a set of standards from scratch, though we acknowledged every standard from adjacent competence fields that was relevant for additive manufacturing, you have a hard time finding a consensus in a fast-moving industry for that reason. Sometimes the standards for additive manufacturing, they are not as specific as some users want them to be. So, in this third phase that I just described, we will have to update the standards and improve the quality besides adding new standards that are currently missing.

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor