Round One

ASTM International’s Additive Manufacturing Center of Excellence has announced its first round of R&D projects. In addition, two innovative research organizations have signed on as strategic partners: Wichita State University’s National Institute for Aviation Research, or NIAR, and Singapore’s National Additive Manufacturing Innovation Cluster, NAMIC. All partners are initiating research projects under the aegis of the AMCOE that will advance the state of the art in additive manufacturing — popularly known as 3D printing — technology.

First Round of Funding

At a September meeting of its committee on additive manufacturing technologies (F42) in Singapore, ASTM International announced its first round of funding to support research that will advance needed standards for additive manufacturing. This investment of US$300,000 and in-kind contributions will help AMCOE partners address pressing technical information needs in this fast-growing area.

“We are very fortunate to work with such renowned organizations to leverage their expertise towards standardization in additive manufacturing,” said Matthew Donovan, who chairs the research and innovation group under Committee F42. Donovan is a principal engineer at Oerlikon.

The initial round of projects approved by the committee, to be carried out by the AMCOE’s founding partners, target four main areas: feedstock, process qualification, post-processing, and testing.

The UK-based Manufacturing Technology Centre will conduct research aimed at developing quality assessment standards for metal powders used in additive manufacturing machines. This feedstock characterization research will contribute to a standard guide that helps people who need to evaluate powder quality and recyclability.

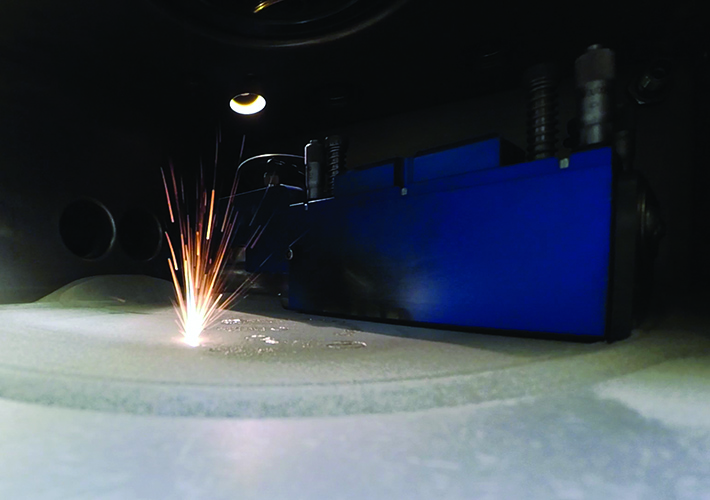

NASA will work to develop standard procedures, metrics, and comprehensive requirements to help qualify machines and processes in laser powder bed fusion. This process qualification and assessment research aims to establish much-needed consensus in this area across the additive manufacturing community.

Applied technology developer EWI will research how various surface finishing techniques for additively manufactured products impact performance and structural integrity. This post-processing research will help standardize surface quality and measurement metrics.

Auburn University will investigate mechanical testing issues with metal additive manufacturing to better understand the relationships between the properties of test specimens and the performance of parts. This study will contribute to a standard that guides how to design specimens (i.e., test coupons) that are most representative of additively manufactured components.

Strategic Partners

NIAR and NAMIC have become strategic partners in the AMCOE, and they are taking on projects as well.

NIAR will focus on mechanical testing issues surrounding polymers used in additive manufacturing. They will look to create guidelines and best practices aimed at applying existing mechanical testing methods in this fast-growing area.

NAMIC will coordinate the center’s R&D and related activities for the Asia-Pacific region while also investing

2 million Singapore dollars (nearly US$1.5 mllion) over two years in R&D activities overall, with a possible extension to five years.

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor