Standards for the Third Dimension

E2807 and the E57 File Format

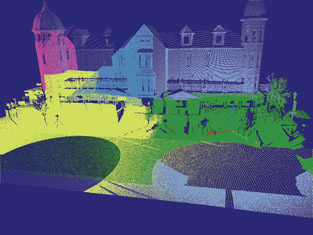

The data used to produce the building scan has been placed in the ASTM E57 file format. Image courtesy of k'nowbe, Salt Lake City, Utah.

An ASTM International standard specifying a 3D imaging data file format, and a related software implementation, gains traction in the laser scanning industry.

A maintenance mistake can be costly.

That's particularly true in the difficult environment of an offshore oil rig, where waves, weather and transportation can complicate getting materials to the rig platform.

For even regular equipment replacement, accuracy of the sizes of the elbows, flanges and pipe is particularly important. All of the related component parts need to be the correct size and shape to fit together within an allotted space.

To map the rig, a company may use laser scanning equipment to record three-dimensional point measurements, often called point clouds or 3D images, and the resulting data can be used by design and fabrication teams to do their part of the maintenance (or other) project while eliminating errors and a need for additional data collection. When these teams are based at a distance from each other, perhaps even in different states or countries, data need to be exchanged accurately.

That's where the E57 file format, detailed in ASTM E2807, Specification for 3D Imaging Data Exchange, Version 1.0, comes in; with its use data can go from one computer system to another - and one team to another - without a hitch. Gene Roe, chairman of the responsible group, Subcommittee E57.04 on Data Interoperability, says of the format, "It's a format to exchange data; it brings together the point cloud and the images so the two are linked."

Laser Scanning

In the two years since the release of the standard and the file format, E57.04, part of ASTM Committee E57 on 3D Imaging Systems, has seen more of the 3D scanning industry incorporate the file format.

Laser scanning takes advantage of optical signals and laser beams to collect high resolution measurements about a landscape, roadscape or building. Systems may work from the air to scan roads and that oil rig, from the desktop for modeling and the reverse engineering of parts, or somewhere in between for buildings and excavations.

The equipment collects huge quantities of data - more than that used in computer-aided drafting, for example - and that data can offer detailed, accurate information. "The data is complex, three-dimensional and intensive to work with," says Fred Persi, a consultant based in Aliquippa, Pa., and an E57 member.

3D scanning instrumentation vendors create writers for the data recorded by their instrumentation, and software vendors create packages that read files so the data can be used. With the E57 file exchange format based on the E2807 specification, which combines binary and extensible markup language (XML) formats, data exchange can be accurate and efficient.

Chris Thewalt is vice president, scanning software business at Leica Geosystems Inc., San Ramon, Calif, which has integrated the file format into its Leica Cyclone point cloud processing software. Thewalt says, "A standard exchange mechanism means that the data can move from application to application in the customer's workflow. In Leica's case, it is obviously good from a hardware perspective, and from the software side allows us to compete on a level playing field with access to data."

Before the Standard

Before the 2011 publication of the E2807 standard, a common format with broad application did not exist. (The LAS format, from the American Society for Photogrammetry and Remote Sensing, is geared more toward aerial sensing.) Scanning equipment produces point clouds, and proprietary formats work within certain parameters, but with the movement of data from one system to another, points could be lost or corrupted. Those wanting to use the data will at times buy multiple systems to ensure that they can put the data to work. But conversion is still needed, and "converting from one to the other … can become a nightmare," says Persi. "Not only does it take a considerable amount of time and resources to do, but it can introduce errors and artifacts into your data." That's time that would be better spent on using the data rather than converting it.

Several years ago, according to Roe, the industry realized this situation would not help professionals working in the field. "It was actually holding back the adoption of this technology," Roe says.

The concern about data exchange, and general performance evaluation for 3D imaging systems, led to a series of workshops conducted by the National Institute of Standards and Technology between 2003 and 2006. The purpose was to consider the need for standards that would enable system evaluation, which had become more commonly used starting in the 1990s.

In an SN article published in 2006, the year that stakeholders organized Committee E57, Geraldine Cheok, research structural engineer, and Alan Lytle, group leader and supervisory research civil engineer, NIST, recounted that manufacturers, users and researchers from academia and government agencies around the world attended the NIST-sponsored workshops. "The workshop participants agreed that standard terminology and methods for assessment and evaluation of the 3D imaging systems were required," Cheok and Lytle wrote.1 The 2006 workshop participants chose ASTM International to develop standards for the field and Committee E57 was established.

Subcommittee E57.04 began its work on data exchange by defining a design document that would map out requirements for the standard. The subcommittee included representatives of multinational corporations, equipment hardware manufacturers and software developers with an international presence, academics and consultants.

Daniel Huber, senior systems scientist at Carnegie Mellon University's Robotics Institute, Pittsburgh, Pa., recounts that the subcommittee established guiding principles for the standard: reliable interoperability, so that data would be transferable between vendors; an open, well documented and freely available format, both unrestricted and vendor-neutral; low development cost for those adopting the format; a design that would be as simple as possible; and the ability to add features in the future without disrupting the core functionality. A small group held weekly conference calls to discuss the work as well as attend twice-yearly in person meetings.

One project requirement stands out: all future versions of the standard are to be backwardly compatible, with the newest version to allow access to original data. That's so a building owner or manager, for example, can refer to - and read - scans from five or 10 years ago when upcoming maintenance requires locating where a pipe or conduit sits in the wall so that technicians can avoid creating new problems.

Implementation: The E57 File Format

Subcommittee E57.04 didn't stop with the E2807 standard. Its members agreed that the group needed to prove that the format would work by creating software to implement the standard, which would demonstrate how to use the format and help prevent misunderstanding. "We felt it was important to have a reference implementation to prove the ideas that we had made were feasible and then also to help people who wanted to adopt the standard," says Huber.

The E57 file format development proceeded closely with much of the standard's development. E57.04 members describe the format as flexible and self-documenting. It can store:

- 3D point data;

- Attributes such as color or intensity; and

- Imagery such as digital photographs.

"Once we published this, it pretty much worked perfectly from day one," says Roe. "Nothing gets lost." Part of the format's success comes with checks built in to ensure data integrity. With other formats, clients may receive corrupt data without even realizing the situation.

In the time since the file format has become available, major hardware and software vendors in the 3D imaging area have incorporated it in their products, with a few doing so early on because they had been involved in its development. In addition to Leica, Bentley Systems, Quantapoint, Riegl and others have declared their support for the format and have implemented it. Overall, Roe reports, more than 100 firms have downloaded the software to date.

Also since format's completion, E57.04 has been assisting companies interested in adopting it. A website for the format collects information about the E2807 standard, the software, an example of the XML portion of the E57 format, extensions, supporting partners and products, frequently asked questions and a user's group. The website also links to the software online under the E57-3d-imgfmt project.

More to Come

Subcommittee E57.04 is considering new options for the standard and E57 file format. The group is looking at data compression and the addition of data extensions that will further support mobile scanning. But these and other iterations of the standard and the file format will be developed while keeping the format compatible with its original version.

Further details about E57.04's work on E2807 and the E57 file format can be found in Huber's paper, "The ASTM E57 File Format for 3D Imaging Data Exchange."

For more information about ASTM Committee E57, check online, or contact E57 staff manager (Kathleen McClung, ASTM International (phone: 610-832-9717).

Reference

1. Cheok, Geraldine, and Lytle, Alan, "Performance Evaluation of 3D Imaging Systems," ASTM Standardization News, Sept. 2006, p. 27.

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor