Synergy: The Additive Manufacturing Center of Excellence

On July 23, the partners in the new ASTM International Center of Excellence in Additive Manufacturing will gather for a signing ceremony at Auburn University's Samuel Ginn College of Engineering. The partners include Auburn university, EWI, Manufacturing Technology Centre, and NASA, along with ASTM International.

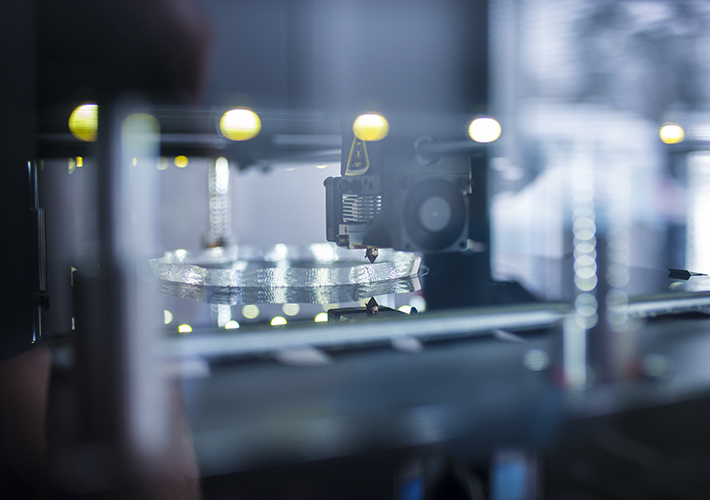

From customized consumer products and medical devices to quickly reproducible parts for planes and cars, additive manufacturing is dramatically changing how we think about making things.

“This game-changing collaboration will build a strong foundation for the future of additive manufacturing,” said Katharine Morgan, president of ASTM International.

New AM materials, technologies, and machines are introduced regularly. Analysts like McKinsey1 say the overall impact of the AM market could surpass $100 billion by 2025.

The need for a technical foundation for this burgeoning area has never been greater. Standards can help ensure that AM will continue to thrive, driving innovation and enhancing our quality of life.

That’s why ASTM International launched its first-ever Center of Excellence this year to focus on AM.

With partners Auburn University, NASA, applied technology developer EWI, and the U.K.-based Manufacturing Technology Centre, the Center of Excellence bridges standards development with R&D.

“This game-changing collaboration will build a strong foundation for the future of additive manufacturing,” said Katharine Morgan, president of ASTM International. “The synergy among the partners — combined with the trailblazing work of ASTM’s additive manufacturing committee — will help fill industry gaps and accelerate innovation.”

The Need to Accelerate AM Standards

In recent years, R&D activities have contributed to standards for innovative technologies in an informal — and often inefficient — way. With rapid technological advances come knowledge gaps — and standards gaps — that need to be filled to allow for widespread innovation and marketplace use.

In 2017, ASTM International identified additive manufacturing as an area that remained greatly affected by this misalignment of the standards and innovation communities.

That’s why ASTM issued a request for proposals in November 2017. The response was enormous, with dozens of inquiry letters and informational webinar participants. Ultimately, a panel of industry, government, and academic leaders examined close to 30 high- quality proposals and interviewed a handful of finalists.

In March, a winning collaboration was announced (Auburn, EWI, and NASA) with an additional non-U.S. partner selected in May (Manufacturing Technology Centre).

Each partner possesses strengths in AM that will play an integral role in the center, according to Brian Meincke, vice president of business development and industry innovation. “They’re going to build something brand new that will help additive manufacturing truly flourish.”

A Look at the COE Operations Plans

In its coordinated efforts aimed at R&D to advance AM standards more quickly, the COE approach involves a dedicated center, national and international partners, and specific projects.

With that as a backdrop, a steering committee and management team will oversee and coordinate key focus areas:

—R&D,

—Standards and certification,

—Education and workforce development, and

—Industry consortia.

Already, the R&D team met in May at Auburn University. At the meeting, the partners and additional representatives from the U.S. Federal Aviation Administration, Food and Drug Administration, and the National Institute of Standards and Technology discussed how the center would plan its project priorities that could be funded by ASTM, the industry consortia, and external sources.

The group identified pressing gaps, such as how to reuse or recycle unused feedstock such as metal powder, how to remove residue after printing, and how to test for fatigue. The group also discussed how R&D coordination should be as broad as possible, involving ASTM’s AM technologies committee (F42) as well as many others related to metals, composites, polymers, and fatigue and fracture.

The R&D work will be crucial to advancing standardization and certification, another major focus of the center.

A recently formed research and innovation task group (F42.90.05) will funnel projects to subcommittees in F42. (See sidebar for more about F42 and other committees who work on AM-related standards.) New standards assignments could focus on feedstocks such as metal powders, test methods for material quality, guidance on applications, and more.

Matthew Donovan, principal engineer at Oerlikon, leads the F42.90.05 group. “The new ASTM Center of Excellence provides a unique opportunity to leverage targeted R&D to advance standards in AM,” he says. “The exceptional expertise provided by the COE partners working with many of the leading experts in the field who make up the F42 committee provides an incredible depth of talent to address the challenges in achieving manufacturing standards. We envision these teams leveraging their combined strengths to apply R&D and close needed standards gaps to enable adoption of AM.”

Ultimately, new standards will further AM by fostering a common language, consistent materials and processes, efficient testing, and applications use. Standards will then strengthen purchaser-supplier relationships, enable repeatable results, and allow performance comparisons.

Furthermore, the next generation of manufacturing professionals can be trained based on developed standards. The center envisions creating industry- university partnerships; promoting education, training, proficiency testing, and certification; and hosting more events, workshops, and symposia.

For example, training offerings could build on ASTM International’s AM webinar series that covers principles, design, processing, and materials characterization and analysis.

In all of the areas described, a partner will be ready to offer their expertise.

—EWI will bring its industry network and its understanding of material processing and characterization as well as testing;

—NASA will bring its global leadership in aerospace and aviation standards;

—Auburn will bring both its R&D expertise as well as its commitment to education and training; and

—U.K.-based MTC will bring its R&D and testing leadership in Europe, leveraging its own National Centre for Additive Manufacturing.

In addition, an advisory board will provide strategic guidance to the steering committee.

A Final Word

For a small company looking to test the possibilities of AM for their industry, or a larger corporation building its AM supply chain, the COE should deliver standards, training, testing, certification, and more.

As Morgan says, “It’s clear that this new center has the potential to shape the future of industries like aerospace, auto, medical, and more.”

Reference

1. Bromberger, Jorg, and Kelly, Richard, “Additive Manufacturing: A Long-Term Game Changer for Manufacturers.”

ASTM International Committees Support AM Standards Work

Several ASTM International committees have created hundreds of standards that advance additive manufacturing in some way.

At the core of this work lies the committee on additive manufacturing technologies (F42). The AM committee has more than 600 members from over 25 countries. Representatives of AM companies large and small, suppliers, academic and testing organizations, government agencies, and consultants have come together both in person and virtually since 2009 to both plan for and to develop standards.

Other committees contribute AM standards as well. Consideration for cleanliness comes through in standards underway in the medical and surgical materials and devices committee (F04), for longer term material performance in the fatigue and fracture committee (E08), for how to test AM goods mechanically (E28), for light metals and alloys material specifications (B08), metal powders and metal powder products (B09), plastics (D20), and composites (D30).

Standards developed by Committee F42 test for metal powder flow rate and specify plastic materials and metal alloys for AM, guide directed energy deposition of metals, and guide principles for purchased AM parts. A number are published as joint standards with the International Organization for Standardization (ISO) through a Partner Standards Developing Organization agreement.

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor