Training for Drone Operation and Maintenance

By now we’re all getting used to the sweeping aerial videos in our social media feeds, the “no way!” news stories about airborne pizza delivery, and that occasional high-pitched whine above our heads while walking outside.

Unmanned aircraft systems, or drones, are flying out of the backyard and into commercial airspace at a rapid clip. The need for standards that support safe operation and proper maintenance has never been more pressing.

Aviation experts — including many members of ASTM International — are playing a key role in the effort to build a framework of standards to support this growth. A number of ASTM International committees indirectly support the growth of UAS (see sidebar), and the UAS committee (F38) itself has been focused for several years on creating standards that support training in operation and maintenance (among other topics). The committee’s comprehensive approach to training-related standards includes piloting, aircraft maintenance, aircrews, and other elements of the UAS ecosystem. Let’s take a closer look at what they’ve been up to.

[Click here to read more about ASTM International's unmanned aircraft standards.]

Part 107

A number of current regulations affect the UAS industry, but probably none more so, at least in the United States, than Part 107 of the Federal Aviation Regulation. It spells out useful parameters for the pilot (in industry parlance, the remote pilot in command, or RPIC), but its relatively narrow mandate reflects gaps in the broader UAS standards landscape — gaps that the UAS committee is rapidly filling in.

Issued in 2016 by the U.S. Federal Aviation Administration, Part 107 covers a variety of commercial uses for drones weighing less than 25 kilograms/55 pounds. For example, It establishes operational parameters for UAS flights. RPICs must maintain visual contact with the aircraft, cannot fly the aircraft over people who are out in the open, and are subject to height (400 feet/122 meters) and speed restrictions (160 kph/100 mph).

Part 107 also requires the RPIC to have some degree of knowledge and experience. Applicants who already have a Part 61 manned pilot certificate must complete a small UAS course online and a flight review within 24 months of applying for the necessary remote pilot airman certificate. For those without any aviation background, the only hurdle to obtaining the certificate is to pass an “aeronautical knowledge test.”

Part 107 does not address pilot training and the standards that trainers should meet. Nor does it address aircraft maintenance or other aspects of UAS management and operations. The members of the UAS committee are working to create standards and an associated training program that will help cover these areas.

Filling the Gaps

“The majority of accidents and incidents in aviation are a result of human factors,” according to Jonathan Daniels, Praxis Aerospace Concepts International Corp., which recently partnered with ASTM International to create the UAS Approved Training Provider Program, which will evaluate the curricula of training programs to see if they are in compliance with standards. As chairman of subcommittee on personnel training, qualification, and certification (F38.03), Daniels has examined the role proper education can play in reducing such mistakes.

One area where he believes standards will help is in spelling out the level of experience a person who trains pilots should have. He tells the story of meeting a helicopter flight instructor who got her remote pilot license through the online course and started a side job as a UAS trainer. She told him she had taught her course several times without ever having taken the written UAS knowledge exam or actually flying an unmanned aircraft.

“Under the current rules, with her remote pilot license, she can act as RPIC for a student who is on the controls, and stand next to him to provide the coaching,” Daniels says. He believes that the updated ASTM International guide for the training of RPICs (F3266), approved earlier this year, is a step toward creating an uniform way for pilots, like the one Daniels cites, to seek and get training.

“F3266 is strong in two major areas,” he says. “It establishes a number of knowledge topics that are not traditionally part of aviation training, and it details a practical flight assessment with repeatable and predictable results.” The latter was included in response to those who have pointed out the lack of such flight assessments in Part 107.

However, Daniels notes that F3266 only applies to RPICs, and does not address the remote pilot instructors, visual observers, and other crew members who may be required for drones larger than the 25-kilogram/55-pound Part 107 maximum.

Maintaining the Aircraft

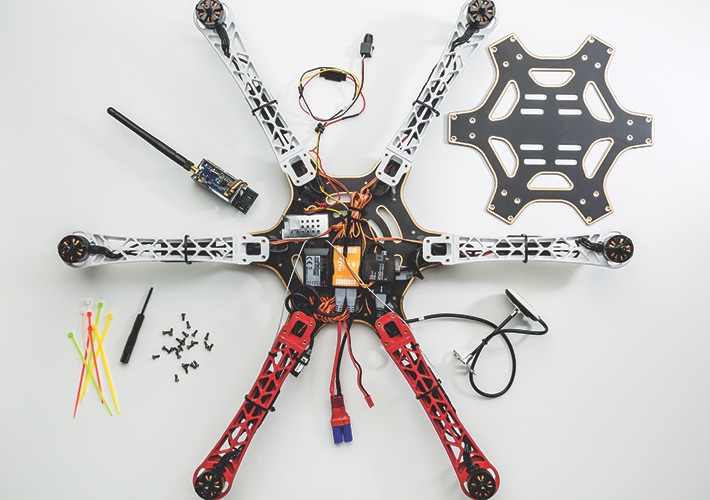

Training the individuals who will in turn train UAS pilots is obviously of crucial importance. But what about the aircraft itself? RPIC qualifications won’t matter much if the drone can’t get off the ground.

Brad Hayden is the president and CEO of Robotic Skies, which operates a global network of over 150 aviation repair stations that do UAS work in addition to handling regular aircraft. Hayden emphasizes that the most important thing to consider when looking at the UAS space is that it really is an emerging market segment of aerospace, not an entirely separate industry. “Maintenance standards and the associated technician training requirements are incredibly important in aerospace, and right now there is no regulatory requirement for maintaining unmanned systems,” he says.

In the absence of such a requirement, service centers in the Robotic Skies network operate using best practices learned from manned aviation when repairing UAS but cannot return these units back to service under their repair station certificate. According to Hayden, the need for maintenance standards geared specifically to unmanned systems is clear.

A work item in progress in Subcommittee F38.03 could become a foundational building block for future UAS maintenance technician standards. Hayden assumed leadership in late 2017 of the group that is working on a draft UAS maintenance technician qualification (WK60659). He notes that key steps included first determining the baseline knowledge a maintenance technician should have. Building on that, he says, the group began to determine “what kind of additional training is going to be required to get them to be in a position where they’ll be fluent in maintaining and repairing these very unique aircraft.”

One of the challenges the work group has dealt with is that very uniqueness. “These aircraft are really flying computers,” Hayden says, “and so it’s going to be incredibly important for maintenance technicians to understand how to get data off the aircraft, how to do software and firmware updates, how to potentially set up Wi-Fi, and so on.” Specialized training centered on the command-and-control link between the base station that’s operating the aircraft and the aircraft itself will also be necessary.

In addition, he says, other skills commonly required of technicians who work on full-size planes will need to be adapted to the UAS environment, including those related to aircraft propulsion systems, structural elements, and avionics equipment.

Even tasks as basic as soldering a connection must be well understood by the repair technician. “It’s not uncommon for us to see things like bad solder joints that were performed out in the field by someone who wasn’t trained properly on how to perform that type of function,” Hayden says.

Hayden believes that the efforts of experts who participate in ASTM International, as well as those of other industry groups and stakeholders, will lead to a fair and robust regulatory regime. “Part of our challenge, across the entire industry, is anticipating where the regulations are going to go,” he says. “The FAA is relying more and more on industry to help guide the regulatory environment, and that includes using more voluntary consensus standards. Utilizing standards that are developed by organizations like ASTM International allow a lot more flexibility to emerging technology than what we’ve seen in the past.”

Synergy among Stakeholders

Clearly, ASTM International is having an impact on the larger world of UAS. Two of its partners are also making crucial contributions to a safer, more productive airspace: the University of North Dakota and the Association for Unmanned Vehicles Systems International.

The University of North Dakota has been a major force in the aerospace industry for 50 years, offering bachelor’s degrees in a number of aviation disciplines, including UAS. In 2009, they were the first to offer an undergraduate degree in UAS operations.

Paul Snyder is the assistant chair and director of the school’s UAS program. “Training standards are important because they ensure that UAS operators have the knowledge, skill, and experience necessary to safely operate unmanned aircraft within the national airspace,” he says. “Within an organization, training standards ensure training consistency and help to ensure students develop the attitude of airmanship required of an aviation professional.”

The basic skills that Snyder sees at the core of a standardized UAS operator training program include:

- Task and automation management;

- Situational awareness risk;

- Mission planning;

- Normal, abnormal, and emergency procedures; and

- Scenario/mission-based skills based on ASTM International standards and future FAA regulations covering areas such as flight over people, flight at night, public safety, and extended visual and beyond visual line-of-sight operations.

UND has expressed interest in becoming one of the first participants in ASTM International’s UAS Approved Training Provider Program, which began evaluating trainers earlier this fall. As explained by Daniels, a consulting technical reviewer for the program, “It is very important in establishing quality assurance for the implementation of these standards. Our primary role will be to review the intended curriculum and facilities for their compliance, repeatability, and predictability of these programs.”

Snyder notes that working closely with ASTM International will better align its programs with industry requirements. “UND Aerospace can leverage ASTM standards to ensure we are continuing to provide the highest quality of education,” he says.

And that is the ultimate goal of all the work being done to create a robust training regimen for unmanned aircraft systems. Perhaps Daniels puts it best: “ASTM F38’s monumental effort to develop and publish these UAS standards started years ago, and we are finally in a position where everything is beginning to align effectively.”

Referring to a “listening tour” undertaken by AUVSI in 2017, Tracy Lamb, vice president of regulatory and safety affairs and chief pilot, says, “The most meaningful feedback we had was that unified standards for both training and operating commercial UAS are severely lacking.” This conclusion represents, in a nutshell, both the rationale for the group’s Trusted Operator Program, or TOP, and the reason its members are working closely with Committee F38 to implement the program.

“ASTM has built, and is in the process of building, extremely robust and very practical standards for the industry,” Lamb says. “What TOP has done is actually taken all of those standards and pulled out the heart, or the protocol. A protocol is a way to implement a standard, and when you flush out a protocol, you really are helping the operator with how they can actually implement these things in the field.”

Lamb and her colleagues believe that delivering practical guidance through these protocols, as well as clear documentation of the standards on which they were built, will result in higher rates of compliance to best practices. “We want to support professional UAS pilots no matter what industry,” she says. “We believe that a commitment to safety, airmanship principles, and a certain level of professionalism is important whether you’re doing wedding photography, agricultural surveys, or hot stack inspection of an offshore oil rig.” //

Beyond the UAS Committee

Many ASTM Committees Support UAS Standards Development

Drones occupy an area between the worlds of aviation and consumer products. Are they sophisticated robots that happen to be able to fly, or just high-tech toys? Can they be both?

This duality is reflected in the fact that — in addition to the UAS committee (F38) — drones are supported by technical committees from both of these industry sectors.

On the aviation side, for example, the committee on light sport aircraft (F37) has developed standards that may be adaptable to the design and construction of UAS airframes. In addition, the avionics and information subcommittee of the aerospace personnel committee (F46) is working on standards that will directly impact F38’s work on UAS training, including a guide for aircraft electronics technician personal certification (F3245) published last year and others covering onboard communications systems and avionics installation that are currently in progress.

But drones can also be bought “off the shelf,” so the committee on consumer products (F15) — specifically, the subcommittee on toy safety (F15.22) — exemplifies the “tool/toy” duality of the UAS market. This encompasses everything from tiny mini-drones for backyard fun to heavy-lift commercial units capable of carrying payloads over 18 kilograms [40 pounds].

Since 2009, all toys sold in the U.S. must meet the safety requirements of the consumer safety specification for toy safety (F963), which is overseen by F15.22. However, Section 1.4 of this standard specifically excludes “powered models of aircraft” from meeting these provisions. Jonathan Daniels notes that several regulatory changes have increased this gap, including one that defines model aircraft as aircraft and another that requires any aircraft weighing more than 0.25 kilograms/.55 pounds to be registered with the FAA regardless of whether it was purchased solely for recreational use.

The key standard specification for the design and construction of smaller, so-called “prosumer” UAS (F2910) — generally defined as those suitable for recreational and simple commercial uses — was developed by F38. One of the thorniest questions facing UAS stakeholders is how to reconcile the requirements of F963 and F2910. Members of F38 and F15 are working together to clarify the intersection points of their respective standards.

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor