The Future of Additive Manufacturing

The Future of Additive Manufacturing

An oral surgeon planning a tricky dental implant surgery. Government officials grappling with a shortage of affordable housing. Engineers looking for a faster and more economical way to manufacture rocket components. The challenges presented in these examples may not seem to have much in common, but they do share a potential solution: additive manufacturing (AM), commonly known as 3D printing.

AM technology makes it possible to produce three-dimensional objects by depositing successive layers of metal or polymer material one atop another, as directed by a computer-aided design (CAD) file that ensures the desired dimensions are achieved. Since the first commercial AM machines were introduced 35 years ago, the industry has evolved into a multi-billion-dollar juggernaut with an ever-expanding portfolio.

ASTM International has provided valuable support since the 2009 formation of its committee on additive manufacturing technologies (F42), which is now home to nearly 20 subcommittees that have produced dozens of consensus-based, globally-recognized standards.

READ MORE: The 5 Most Important Standards in Additive Manufacturing

ASTM further expanded its commitment to AM in the areas of standards, education, and workforce development by establishing a global Additive Manufacturing Center of Excellence (AM CoE) in 2018. And just two years ago, ASTM acquired the industry-leading Wohlers Report — now published as Wohlers Report, Powered by ASTM International — which has tracked the industry and provided unmatched market intelligence for 35 years.

Now in its 28th year, the report itself is a trustworthy and influential information source for those interested in the current state of the industry as well as its future prospects.

Early Adopters

Aerospace was one of the first major market segments to embrace AM. Starting in the mid-1990s, industry heavyweights such as Boeing, Airbus, Lockheed Martin, and Northrup Grumman saw the advantages AM offered for production of non-structural jet and helicopter components in areas like weight reduction and achievable part complexity.

Using 3D printing to produce lighter versions of parts like brackets, air ducts, and mounting holders for wire and cable harnesses might not seem that significant in comparison to the overall weight of an aircraft. However, even small changes can translate into major savings on fuel costs especially when scaled across an entire airline fleet.

These and many other innovative applications continue to drive increased use of AM in the aerospace segment. The Wohlers Report 2023 asked AM companies which industries they serve and the approximate revenues (as a percentage) they derive from each, and aerospace ranked third in terms of revenue, at 13.9%, among companies that shared data for the 2023 edition. (Automotive topped the list at 15.8%, with consumer products next at 14.5%.)

With decades of proven performance, AM is well-established in the commercial aircraft industry. The technology is also making inroads with those who seek to, paraphrasing poet John Gillespie Magee Jr., “slip the surly bonds of earth” on the way to outer space.

AM in Space Vehicles

Launched by the company Relativity on March 23, Terran 1 was the largest 3D-printed object ever to attempt orbital flight. By mass, 85% of it was manufactured using AM, including all ten of its Aeon engines. (Relativity’s target is 95% by mass.) The two-stage prototype, which was 33.5 meters (110 feet tall) and just over 2 meters (7.5 feet) in diameter, achieved lift-off but failed to reach orbit due to an engine issue.

Though Terran 1 did not reach its ultimate goal, John Vickers was duly impressed. “This is groundbreaking in terms of cost and schedule savings,” says Vickers, principal technologist for advanced manufacturing with the U.S. National Aeronautics and Space Administration (NASA).

He adds that even though it’s early in the development of this technology, the benefits of faster, cheaper manufacturing of rocket components are clear. NASA’s Rapid Analysis and Manufacturing Propulsion Technology (RAMPT) is one of several projects that demonstrate the agency’s commitment to explore AM’s potential.

RAMPT is a partnership with Auburn University’s National Center for Additive Manufacturing Excellence that focuses on production of rocket engine parts using 3D printing. One rather spectacular result of this effort is a 1,820-kilogram (4,000-pound) nozzle.

“This nozzle is for our RS25 liquid fuel rocket engine,” Vickers explains. “It normally takes more than a year to build, and many millions of dollars. The current design has hundreds of integral cooling channels, individually brazed together. It’s been that way for 50 years.”

The Wohlers Report notes that complex rocket engine parts like the nozzle are a growing market for AM, which enables the nozzle’s conformal cooling channels to be integrated into the design. The report features a photograph of the AM nozzle, which was manufactured using directed energy deposition (DED) in less than half the time required for traditional techniques, and at a much lower cost.

3D Printing in Space — And on the Moon?

The availability of economical 3D-printed rockets like Terran 1 will be a boon to government agencies and private companies looking to place lightweight satellites into orbit. Meanwhile, NASA is exploring another space-related use case for AM: parts manufacturing in a micro-gravitational environment.

The first flight of the On Orbit Servicing, Assembly, and Manufacturing (OSAM-2) mission is scheduled for 2024. In the words of Redwire, the private firm spearheading the effort for NASA, OSAM “unlocks the possibility of scalable space architectures that cannot currently be stowed and launched from Earth. The ability to construct large, self-assembling structures in space revolutionizes the economics of space infrastructure.”

Vickers provides more details. “They have a small satellite with which they plan to 3D-print two truss structure beams, and at the same time deploy solar arrays from those beams. These are small, only 10 meters (33 feet) in length, but this is just a development mission. The idea is that in the future, we could do this at a 100-meter [330-foot] scale.”

Projects like OSAM-2 are intended to lay the groundwork for a robust in-space AM infrastructure. The eventual goal, according to the Wohlers Report, is to be able to print things like sensors, electronics, and metal parts. That infrastructure capability will prove crucial as NASA continues to push forward on its biggest initiative: the Moon to Mars program.

“We’re going to go to the moon as a proving ground and build an outpost there, with the idea that we’ll develop the technology and knowledge to get us to Mars in a more sustainable fashion,” Vickers explains. Maintainability, reuse, and recycling are key tenets of the plan.

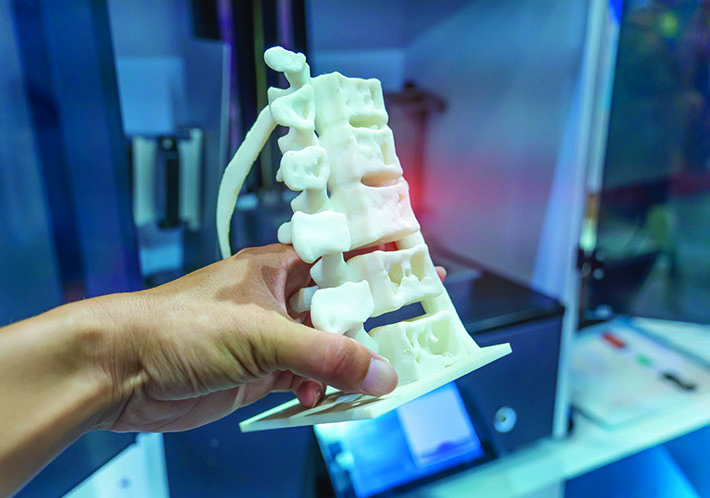

3D printing is revolutionizing industries such as the biomedical field.

To that end, NASA is exploring the potential of in-situ resource utilization, which is essentially the ability to use local — in this case lunar — materials as AM inputs. “This project is focused on taking material on the lunar surface, extracting metal, and transforming it into feedstock for additive manufacturing,” says Vickers. “We believe AM has the most utility, the most flexibility for doing as many things as we can on the lunar surface.”

The first phase of this project is to figure out how to extract aluminum from lunar regolith — the layer of loose rock, dust, sand, and soil resting on the moon’s bedrock — and turn it into wire for a DED additive manufacturing process.

3D Construction and Sustainability

The Wohlers Report states that additive construction (AC) “has seen increased activity in the past few years, with a proliferation of dedicated systems and services,” and that the scope of AC projects continues to expand into multi-story structures and large-scale 3D printing. Examples cited include a villa in Saudi Arabia and a 100-home development in Texas (each of which incorporates 3D-printed walls) and an Italian prototype that will employ AC technology using “locally sourced earthen materials.”

The latter project highlights one way AM can contribute to greener construction practices. Whether it’s 3D printing with ingredients derived from local soil in Italy or converting recycled plastic waste destined for a landfill in New Jersey into polymer reinforcements for concrete, the ability of the technology to adapt to different feedstocks is one of its strongest attributes.

Stephan Mansour, an associate consultant with Wohlers Associates, cites a residential prototype in the state of Maine that illustrates both the recycling potential and the scalability of AM technology.

Unveiled just last November, BioHome3D is a 600-square-foot showcase for sustainable construction practices and the promise of large-scale AM. According to the University of Maine (which collaborated with Oak Ridge National Laboratory on the project), it is the first fully biobased house.

In this context, “biobased” means that each entire module — walls, floor, and roof — was manufactured from a combination of local wood fiber and bio-resins. This approach differentiates the home from structures that combine 3D-printed components, like wall panels, with metal or wood framing and other non-AM elements. The modules were printed off-site for ease of transportation and assembly, and the materials used were 100% recyclable.

Mansour notes that the ability to adapt and use locally available materials as feedstocks is an important advantage of AM. “The University of Maine printed their house out of wood dust since wood is an abundant natural resource in the region.”

Point-of-Care AM

The precision and customization that can be achieved with AM are especially important in critical applications involving medical and dental procedures. For example, AM facilitates the creation of one-off, patient-specific designs for anatomical modeling and implants. It also makes possible more complex device designs, such as porous metal structures that promote bone in-growth, which are impossible to produce using traditional manufacturing methods.

These and many other innovative applications are driving increased use of AM in the healthcare segment. The Wohlers Report puts it at number six among industries served by AM companies that shared data for the report, at 12.1% of total revenues.

Advances in AM systems and the software that supports them are also contributing to a shift from reliance on third-party AM providers toward in-house production. According to Andy Christensen, president of consulting company Fingerprint Additive LLC, “Point-of-Care (POC) AM refers to the growing movement of healthcare providers, both hospitals and individual physicians, manufacturing medical devices on-site.”

This trend represents a significant shift in the way such devices are produced. In the dentistry realm, for example, medical imaging information like CT scans would traditionally be sent out to AM companies that would then manufacture the requested item. POC AM enables this work to be done right in the office.

Christensen offers the example of an oral and maxillofacial surgeon preparing for dental implant surgery. Specialized software allows the surgeon to use the results of in-office 3D imaging to plan the position of the implants and design a customized surgical guide that will fit into the patient’s mouth, serving as a template for the surgical drill. The guide is then 3D printed in a biocompatible material that can be sterilized for surgery.

“This scenario is becoming more prevalent today for procedures that can happen in the office setting,” Christensen states. “In addition to dental implant guides, which are fairly simple, anatomic models and surgical guides for more complex repositioning of upper and lower jaws are also being produced.” He estimates that about 15% of this type of AM work is now done in a point-of-care setting.

FOR YOU: A New Way to Build

Moving to the medical side, centralized departments for 3D printing are being established within the hospital environment. “Many of today’s best applications for the use of 3D printing in healthcare are related to surgeries that happen in hospitals, such as fixing broken bones, spinal fusion procedures, and total joint replacements,” Christensen says. “In the last 10 years, we’ve gone from close to zero facilities in the U.S. doing this work internally to as many as 200-plus hospitals with centralized labs.” He predicts the percentage of the overall medical market represented by point-of-care 3D printing will at least double in the next five to ten years.

Inspiring the Next Generation

Research cited in the Wohlers Report describes 2022 as “one of the busiest years to date in the AM talent and job market.” The good news: An industry headhunter made 32% more placements compared to the previous year. The bad news: major layoffs left many without jobs.

The large number of experienced AM professionals now looking for new positions is one element of the current employment landscape. Another issue is a broader one that impacts all high-tech industries, including AM. It is the confluence of an aging workforce and the shrinking number of young people drawn to the science, technology, engineering, and mathematics (STEM) disciplines.

A study commissioned several years ago by the National Association of Manufacturers showed 2.1 million unfilled jobs in the manufacturing sector by 2030. It’s also widely acknowledged that only about 20% of high school graduates pursue STEM-related degrees in college.

The numbers aren’t better in the construction industry. “There are many statistics out there that show the labor force is actually shrinking,” notes Mansour. “The average age of the construction sector worker is about 55 to 60 and many will soon retire. The younger generation is not exactly enticed to come into this sector. Nobody wants to be outside, exposed to the elements, doing hard physical work.”

Mansour believes additive manufacturing presents an attractive alternative. “With AM you are introducing automation, robotics, computing, and 3D design. You don’t necessarily have to do the heavy lifting anymore or be exposed to hazardous environments such as working at heights. Robotics, 3D modeling, and other innovative technologies could be the means to entice the younger generation to consider a future in construction.”

Vickers hopes that promoting the important role AM is poised to take on in future space expeditions could also help improve those numbers. “I believe the space industry has always had the power to inspire and excite young people. We have an entire office, one of our primary offices at NASA, that’s called the Office of STEM Engagement,” he says, adding that the program runs from K-12 through advanced degrees and features opportunities in AM.

“The White House, through the National Science and Technology Council of the Office of Science and Technology, also has a roadmap specifically focusing on diversity, inclusion, equity, and accessibility to ensure that under-represented groups are recruited and supported in their efforts to pursue technical fields. The automated nature of AM opens unique possibilities for those who might have shied away from things like construction work. “For example, a person with physical limitations who normally wouldn’t be on a typical construction site can actually manage a robot or machinery remotely to do the work,” says Mansour.

“It’s a combination of standards development and technology.”■

View the full 2023 Wohlers Report.

Jack Maxwell is a freelance writer based in Westmont, N.J.