Low-Density PVDF-Based Material

A new ASTM International standard will provide aspecification for low-density poly vinylidene fluoride (PVDF)-based materials intended for use in wire and cable jacketing. ASTM’s committee on electrical and electronic insulating materials (D09) developed the standard, which will soon be published as D8318.

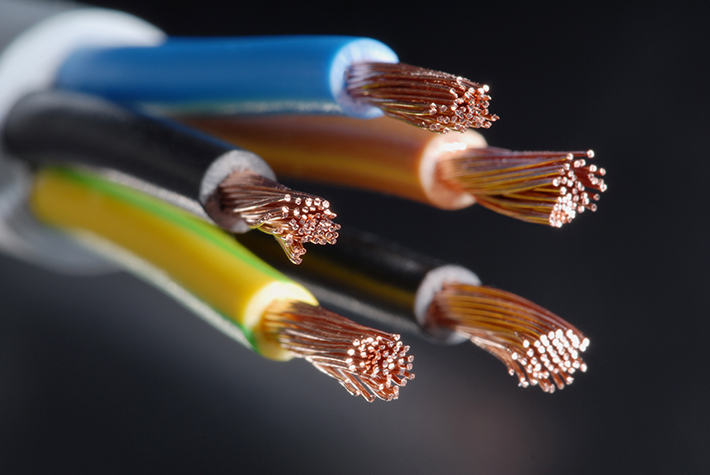

Low-density PVDF cable jacketing is a new product that has the potential to offer advantages in terms of being lightweight, exhibiting easy strippability, high flexibility, reduced dielectric constant, resistance to weathering, and good fire performance. This specification outlines the material performance properties that can be expected from a jacket made of foamed PVDF.

“Low-density PVDF jacketing is already in use in fire alarm cables, due to the properties above, in various applications, including the area of building plenums, where very high fire performance is required,” says ASTM member Marcelo Hirschler, president of GBH International. “The new specification will encourage the use of the material in other applications.”

According to Hirschler, the new standard will be found useful by wire and cable manufacturers because they will be able to offer lower cost cable constructions with improved fire performance which also have high quality and chemically resistant jacketing. In addition, engineering professionals will find the concept of such low density materials useful for high performance designs in various industries including construction, mining, oil exploration, marine, or food and beverage.

To purchase standards, contact ASTM International customer relations (tel +1.877.909.ASTM; sales@astm.org).

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor