New Composites Standard Helps Test Sandwich Panels

A new ASTM International standard will help test “sandwich” panels, which are flat, lightweight, durable products often used in the cabin floors and other areas of airplanes. The new standard (D8067, Test Method for In-Plane Shear Properties of Sandwich Panels Using a Picture Frame Fixture) was developed by the Committee on Composite Materials (D30).

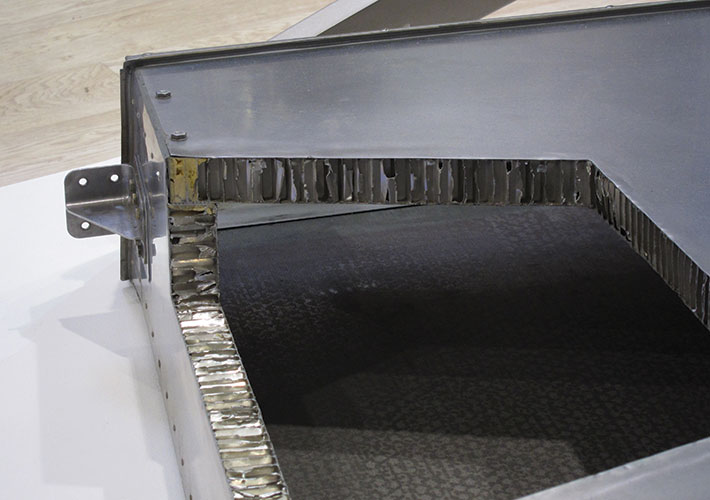

Specifically, the standard helps determine in-plane shear strength and stiffness properties of sandwich panels, which have cores made of either continuous bonding surfaces (e.g., balsa wood, foams) or discontinuous bonding surfaces, such as honeycomb. The “picture frame” fixture used in the test involves pinning the corners of the panel and pulling opposite corners at the same time.

Versions of this test method have already been used in the aerospace industry for design and quality control. But the standard could be even more broadly used by aircraft designers, manufacturers and suppliers, and test laboratories, according to ASTM member Stephen Ward of SW Composites.

ASTM Committee D30 on Composite Materials Next Meeting: Oct. 11-12, 2017, October Committee Week, New Orleans, La.

Technical Contact: Stephen H. Ward, SW Composites, Chula Vista, Calif., tel +1.619.691.2281

ASTM Staff Contact: Krista Robbins, tel +1.610.832.9689

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor