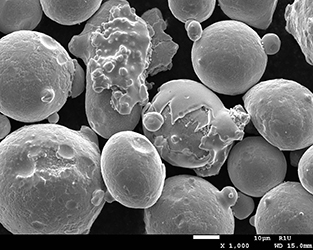

Properties of Metal Powders for Additive Manufacturing

High grade biomedical implants and automotive and aerospace parts are among the objects that can be made from metal powders using additive manufacturing processes. The makers and users of metal powders will be among those who will benefit from a new ASTM International standard, F3049, Guide for Characterizing Properties of Metal Powders Used for Additive Manufacturing.

John A. Slotwinski, Ph.D., a physicist at the National Institute of Standards and Technology and an ASTM member, notes that the new standard will help those who are faced with the large number of existing standards for metal powder properties.

"F3049 will point readers to existing metal powder standards that may be appropriate for additive manufacturing powders," says Slotwinksi. "It will provide one-stop shopping for someone who may want to measure the properties of AM powders but doesn't necessarily know what standard methods exist."

In addition to F3049, Slotwinksi says that a companion standard covering the mechanical properties of metal parts, WK43112, Guide for Evaluating Mechanical Properties of Materials Made Via Additive Manufacturing Processes, is also in the works.

F3049 was developed by Subcommittee F42.05 on Materials and Processes, while WK43112 is under the jurisdiction of Subcommittee F42.01 on Test Methods. Both subcommittees are part of ASTM International Committee F42 on Additive Manufacturing Technologies.

CONTACT Technical Information: John A. Slotwinski, Ph.D., National Institute of Standards and Technology • Gaithersburg, Md. • Phone: 301-975-2171 | ASTM Staff: Pat Picariello • Phone: 610-832-9720 | Upcoming Meeting: Jan. 26-27, 2015 • ASTM Headquarters, West Conshohocken, Pa.

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor