Powering the Future

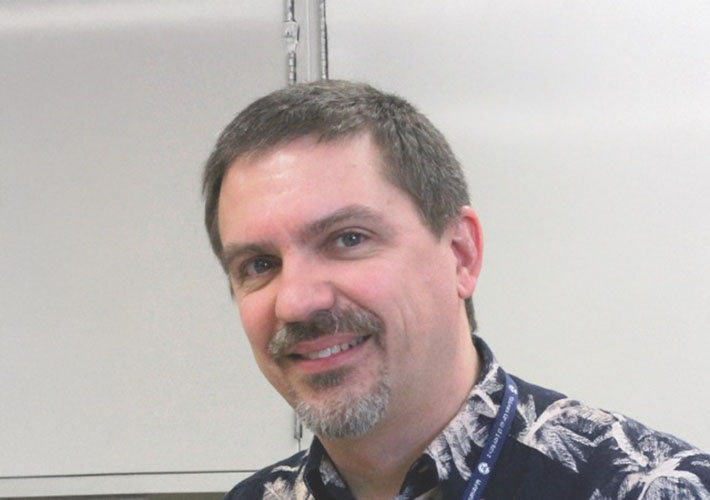

Nuclear energy had a big year in 2024. New government projects broke ground and older ones were renewed. Plant Vogtle Unit 4 entered commercial operation, making the Waynesboro, Georgia plant the largest clean power generator in the country, according to the U.S. Department of Energy (DOE). The Biden administration also released goals to expand nuclear capacity by 200 gigawatts by 2050, and President Biden signed the ADVANCE Act, which could allow for the increased production of new reactors. The DOE’s Office of Nuclear Energy also surpassed $1 billion in total funding used to advance nuclear energy research, as well as training at U.S. colleges and universities. I spoke with J. Brian Hall, chair of ASTM International’s committee on nuclear technology and applications (E10) and fellow engineer at Westinghouse, to learn more about the future of the industry.

Q. Can you discuss some recent trends in the field and what you think the industry will look like in the near future?

A. The nuclear renaissance stalled in 2011 thanks to the trifecta of the tsunami destruction of the Fukushima nuclear plants, low natural gas prices, and a weak global economy. However, the U.S. nuclear industry reached a turning point after Indian Point closed in 2021 and the decision to close Diablo Canyon was reversed.

Now, thanks to growing demand from data centers, artificial intelligence facilities, and electrification efforts, many countries and organizations want more nuclear energy. In Europe, the key trend involves energy supply security because its demand cannot be met with intermittent, land-intensive renewable energy. Nuclear energy offers a dependable, cost-effective power source. However, building new, large nuclear plants requires long-term effort and significant upfront capital investment. Investors have reacted by supporting the restarting of recently closed nuclear plants. Restarting old plants can happen in just two or three years—requiring significantly less time and money than building new plants. Plans to restart both the Palisades plant in Michigan and Three Mile Island in Pennsylvania promote safe and cost-effective power supplies through their remaining licenses and for at least another 20 years.

Q. When discussing renewable energy, people often think about other sources (solar or wind) before nuclear energy. Yet nuclear energy provides about 20% of the electricity generated in the U.S. Do you see that percentage increasing in the near future?

A. In the near term, the percentage of our nuclear-generated electricity will not increase much but should grow over the longer term. Current near-term activities include restarting recently closed plants and extending the U.S. operating fleet licenses from 60 to 80 years. Increasing output from existing plants through power uprates and longer operating cycles is also happening. Most production increases for the past 20-30 years came through uprates and increased capacity factors (percent of time the plant is at full power). The construction and commissioning of Vogtle Units 3 and 4 in 2023 and 2024 were the first new builds in the U.S. since 1990. With few plans to build large plants in the U.S., the focus has shifted to building smaller reactors.

Q. How has nuclear technology evolved in recent years, and how might that help its application become more widespread?

A. The nuclear industry has attracted lots of excitement over the past decade. Many startups emerged, developing new designs and increasing competition in the market. Westinghouse, my company, currently operates six large baseload Gen III+ AP1000 units (1,100 Mwe) worldwide, with 12 more under construction and five under contract. That AP1000 technology has been integrated into my company’s AP300 small modular reactor design, too, reducing deployment risks and construction costs.

At the other end of the scale, microreactors are being prioritized, and my organization is hoping to produce 5 Mwe with current proprietary designs. These reactors can be moved to site in three shipping containers and set up very quickly. They are designed for remote, off-grid locations such as cold climates, islands, mining sites, military bases, and even the moon.

Q. How have standards affected the development of nuclear technology in the U.S., or globally?

A. The entire nuclear value chain relies heavily on standards to operationalize safety, requiring industry consensus around materials standards, test methods, and design methods. For instance, regulators depend on them to make informed decisions about safety approval. Standards provide designers with properties, dependable test results, best practices, etc., for integrating into designs. Customers and operators rely on standards to make decisions and ensure dependability of materials used.

Q. What are some challenges to expanding nuclear energy?

A. Two major challenges facing expanding nuclear energy include high upfront costs and public perception. Construction delays of new nuclear facilities not only lengthen the time to operation but also drive higher costs. However, applying lessons learned, developers promise dramatic improvements on construction times and costs. In fact, several Eastern European countries have committed to ensuring their energy security and have initiated construction of large nuclear plants.

Nuclear accidents are very high-profile events garnering lots of attention and fear. But it is important to note that even amid the Fukushima nuclear disaster, there were no injuries or deaths from radiation exposure. From a MW-hour production standpoint, nuclear energy remains one of the safest forms of electricity production and, once operating, remains cost-competitive.

Q. Can you discuss your career path and how it led to you working with ASTM?

A. Participation in ASTM over the years has been very valuable for me and the industry I represent. Being involved with reactor pressure vessel embrittlement surveillance early in my career brought me to the ASTM committee on nuclear technology and applications (E10). This committee is responsible for standards related to measuring neutron exposure of nuclear structural components and monitoring material degradation among other related areas. The U.S. Nuclear Regulatory Commission and many international regulators recognize and depend on these standards. The U.S. fleet of reactor operators and designers support the active updating and maintaining of these standards.

Because these standards are directly relevant to the continued operation of the aging reactors, it is important to keep these standards updated and relevant. For example, with higher neutron exposure, the E10.02 subcommittee maintains the standard guide for predicting radiation-induced transition temperature shift in reactor vessel materials (E900), so that new higher neutron exposures are still predicted properly as the U.S. fleet ages and operates for 60 to 80 years and beyond. Our committee regularly sponsors symposia where experts present research findings published in ASTM special technical publications.

Over my career, I have made invaluable connections collaborating with ASTM members who are expert plant designers, operators, U.S. regulators, and national laboratory researchers (some of the most experienced experts in the field) to learn and solve problems, sometimes beyond standards development. In addition, continued participation in the standards-development process helps me understand some of the underlying reasoning for the language contained in the standards. The E10 committee has significant international participation, with some attending in-person regularly. Therefore, I try to keep the meetings relevant and include technical presentations related to the standards that help keep attendees informed and engaged. I am also active on the fracture toughness and mechanical test method committees (E08 and E28). ●

J. Brian Hall is fellow engineer in materials innovation at Westinghouse Electric Company. He received the B.S. in engineering and M.S. in engineering mechanics from Pennsylvania State University. He has 30 years of experience in the nuclear power industry, working with material specifications for component replacement and new plants; failure analysis; materials testing; fracture mechanics; and material-aging evaluations for uprates, repairs, and license renewal. His contributions have been in the areas of reactor vessel (RV) integrity; RV internals aging; and other reactor coolant system materials.

SN Home

SN Home Archive

Archive Advertisers

Advertisers Masthead

Masthead RateCard

RateCard Subscribe

Subscribe Email Editor

Email Editor